功能特點

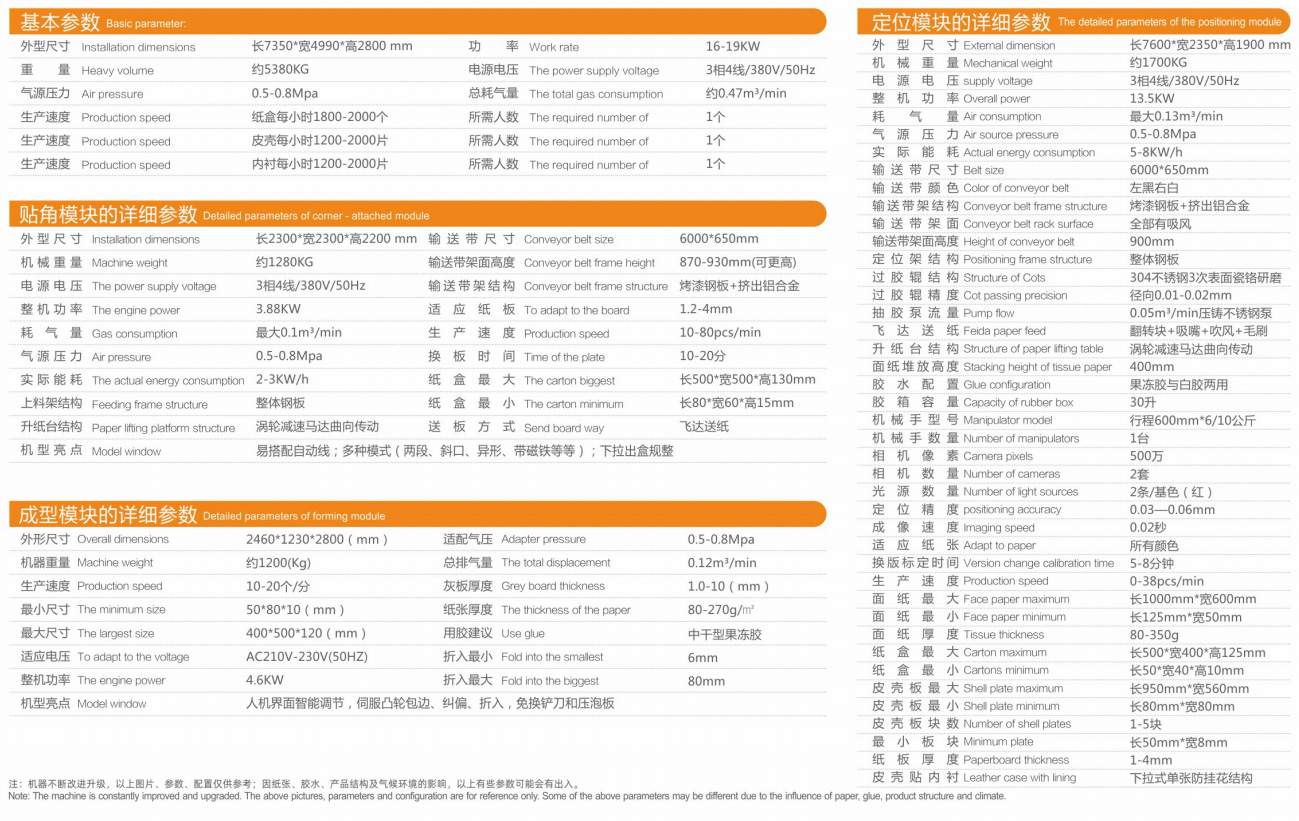

該機主要分為定位模塊、貼角模(mó)塊和(hé)成型模塊三大部分,可實現各類紙盒、木盒、膠盒生產時的(de)自動送紙、自動過膠、自動貼角、自動(dòng)定位、自動成型和(hé)自動壓泡(pào)等(děng),係列(liè)工藝工序的自(zì)動完成,轉版(bǎn)速度快,製作盒體精美。定位模塊的(de)黑白(bái)皮帶、雙鏡頭、自動糾偏、皮殼板貼襯定位(wèi)、五片板定位。貼角模塊的不粘膠(jiāo)膠帶槽、雙升(shēng)紙台。成型模塊的智能調節、自動鎖固、伺服凸輪動作、免(miǎn)換鏟刀和壓(yā)泡板等,均由我司自行研(yán)發設計生(shēng)產,並獲得多項國(guó)家專利(lì)。

Features

The machine is mainly divided into three parts: positioning module, angle sticking module and forming module. It can realize automatic paper feeding, automatic glue passing, automatic angle sticking, automatic positioning, automatic forming and automatic bubble pressing in the production of all kinds of cartons, wooden boxes and plastic boxes. It can complete a series of technological processes automatically, transfer plates quickly, and produce exquisite boxes. The positioning module includes black-and-white belt, double lens, automatic deviation correction, skin plate lining positioning and five plate positioning. Non adhesive tape slot and double lift paper table of corner module. The intelligent adjustment, automatic locking, servo cam action, no change blade and pressure foam board of the molding module are designed and produced by our company, and have obtained a number of national patents.

微信公眾號

微信公眾號 微信小程(chéng)序

微信小程(chéng)序

微信公眾號

微信公眾號 微信小程(chéng)序

微信小程(chéng)序

手機網站

手機網站